| |

| |

| |

|

|

Sept. 28, 2018 |

|

| |

Download a high-resolution poster that is a quick and easy reference to frequent biomass conveyor hazards and their solutions.

» Read more...

A new biomass power plant to be built for ENCE Energía & Celulosa in Huelva, Spain by Spanish general contractor SENER will have two Samson Material Feeders.

» Read more...

A North American pulp mill upgraded its hog fuel, wood chip handling equipment to reduce significant dust and spillage issues from old worn out transfer chutes.

» Read more...

“This is a true partnership between two strong brands, Siwertell and BRUKS, as they complement each other very well both in terms of product portfolio and market coverage,” Per Karlsson, managing director of Siwertell, said in the release.

» Read more...

Forest Concepts has been awarded a $1.8 million co-operative agreement from the U.S. Department of Energy to address poor flowability, high friction, and highly variable physical properties that have plagued the biomass industry.

» Read more...

|

| |

|

|

| |

|

| |

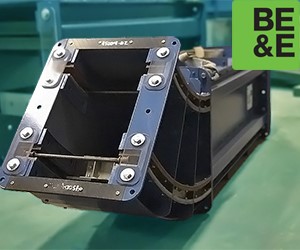

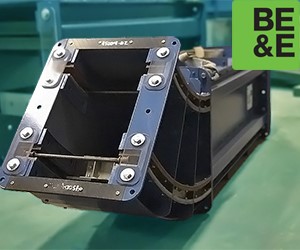

SMART conveyors from Biomass Engineering & Equipment are highly refined, modular machines that allow for wide customization. These twin-chain drag conveyors boast unmatched inclines—up to vertical—energy efficiency, simple maintenance, and reliable operation that will continue for years. BE&E is so confident in the conveyors that they back them with the industry’s leading warranty. Contact them to learn how their products deliver on their slogan: Superior Engineering, Superior Performance.

>> Learn More |

| |

|

| |

From belt construction, to structural composition to splicing considerations, having fundamental knowledge of conveying systems can provide enhanced belt performance outcomes.

» Read more...

From belt construction, to structural composition to splicing considerations, having fundamental knowledge of conveying systems can provide enhanced belt performance outcomes.

» Read more... |

| |

Canadian Biomass narrows in on material handling options, from small wheel loaders, to walking floors and bagging lines, available to customers in Canada.

» Read more...

Canadian Biomass narrows in on material handling options, from small wheel loaders, to walking floors and bagging lines, available to customers in Canada.

» Read more... |

| |

|

|

| |

|

| |

Wolf Material Handling Systems offers versatile Underpile Reclaimer platforms that automatically reclaim and evenly meter all wood fuel products including: granular, chipped, hogged and even tub-ground fuels. These robust and innovative designs include low profile offerings that can be incorporated into almost all new or retro-fit applications. Engineered with ease of maintenance in mind these systems are engineered to provide easy access to wear parts and include a slow speed chain design with VFD drives to further reduce wear. Other standard offerings include hardened chains and heavy-duty frame construction that allow “drive over” capability and provide years of service.

>> Learn More |

| |

|

| |

The Prince George, B.C., pellet plant has installed a ClassiCleaner, which uses a combination of roller screening and air separation units to filter out contaminants before fibre enters the hammer mills.

» Read more...

|

Don’t let emergency stop buttons and pull cords lull you into a false sense of security. Here are six types of solutions to ensure conveyor safety.

» Read more...

|

|

In 2017 the Wood Pellet Association of Canada Safety Committee created a new safety working group to facilitate the development of proposed guidelines around storage and infeed processes.

» Read more...

| | |

|

| |

|

|

| |

| |