|

|

|

|

|

|

|

|

It's So Hot!

|

|

|

|

Besides the obvious affect that hot weather has on workers, heat can also reduce the performance of the electrical and mechanical components of the production process. Sensitive electronic controls are more likely to overheat, pieces that were heated during a procedure will take longer to cool down to a manageable temperature, and working surfaces can quickly become too hot to properly finish in a milling, grinding, rolling, or stamping job.

|

|

|

|

EXAIR Offers Relief for All of These Problems

|

|

|

|

|

|

Cabinet Cooler Systems

|

|

|

|

The high temperatures and dusty environments of most factories are the enemies of sensitive electronic controls. Dust intrusion can be mitigated by placing electronics in a dust-proof enclosure but that usually won't relieve the heating problem. Since overheated controls can lead to nuisance tripping, circuit drift, or even a complete failure of the system, it's a high priority to find a solution.

|

|

|

|

|

EXAIR's compressed air powered Cabinet Cooler® Systems are engineered to keep controls both dust-free and cool. Using a small amount of compressed air, they produce a cool, clean flow of air that will maintain proper operating temperature and a higher enclosure pressure which will help to keep dust and dirt out.

|

|

|

|

|

|

|

|

|

|

|

Super Air Knives

|

|

|

|

|

|

EXAIR's Super Air Knife very efficiently produces a quiet, hard-hitting curtain of air for cleaning, drying and cooling on webs or conveyors. Both compressed air usage and noise are dramatically lower than other blowoffs. To provide edge-to-edge cleaning, it has been engineered to deliver a uniform sheet of laminar airflow across its entire length. Even at high pressures of 80 PSIG (5.5 BAR), the sound level is surprisingly quiet at 69dBA for most applications — well below OSHA workday limits. Super Air Knives are available in stock lengths from 3" (76mm) to 108" (2743mm) in aluminum, Type 303 stainless steel, Type 316 stainless steel, and PVDF.

|

|

|

|

|

|

|

|

|

|

|

|

|

Cold Gun Aircoolant Systems

|

|

|

|

An alternative to messy and expensive mist cooling, EXAIR's Cold Gun converts compressed air into a focused stream of cold air that's ideal for cooling parts and tooling during machining operations. The Cold Gun produces a stream of clean, cold air at 50°F (28°C) below supply air to keep parts cool, clean, and dry — an invaluable tool for machining a wide range of plastics, hard metals and other materials that may become contaminated when using traditional coolants or oils. Cold Guns have a quick mount magnetic base and flexible cold air outlet that make it easy to position for optimal cooling and debris removal.

|

|

|

|

|

|

|

|

|

|

|

|

|

|

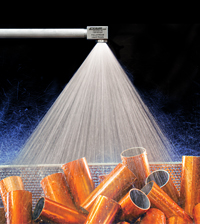

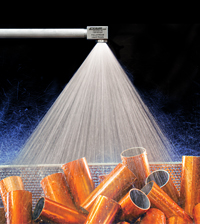

Liquid Atomizing Spray Nozzles

|

|

|

|

|

A new EXAIR product, Liquid Atomizing Spray Nozzles generate an atomized spray using only supplied liquid pressure. No compressed air is required. They are commonly applied to solve cooling, cleaning, washing, rinsing and dust suppression applications throughout industry. Their design is vaneless, which creates wide open internal features to resist clogging and can work well with liquids containing particulate. Their right-angle design is compact and operates up to 250 PSI liquid pressure. They are commonly used with liquids like water, rinse aids or detergents but are also effective with chemicals, pesticides and herbicides. EXAIR's Liquid Atomizing Spray Nozzles are currently available in two spray patterns: a solid cone (FullStream) or a hollow cone (HollowStream).

All EXAIR Liquid Atomizing Spray Nozzles are constructed of durable, corrosion-resistant type 303 stainless steel.

|

|

|

|

|

|

|

|

|

|

|

Current Promotion

|

|

|

|

|

|

|

| | |