|

|

|

|

| |

As robots play a bigger and bigger role in automated production, Columbia Marking Tools now provides complete marking stations for robot work cells.

CMT's air impact markers have been a preferred solution for industrial manufacturing for over half a century. These compact systems provide a quick easy mark - from a station identification, to a part number, or date code. CMT's air impact markers are a low cost solution to dot-peen and laser marking systems. In addition, these rugged marking units have a speedy cycle time, and provide a deep legible mark.

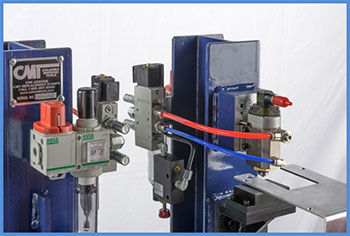

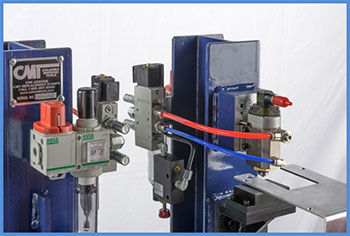

Figure 2 Close up of Mite-E-Mark with sheet metal part

Air impact markers provide a very intense impact and CMT recommends the use of a part rest during the marking process. The part rest can be designed to hold the part while the robot does other operations, or as shown, just a small back-up detail.

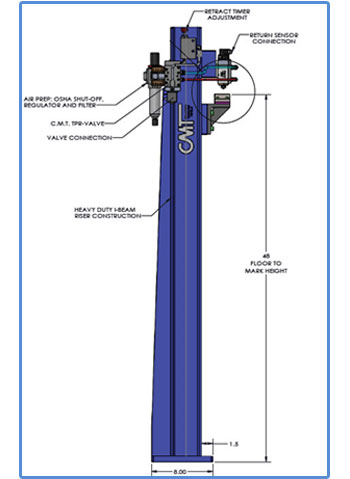

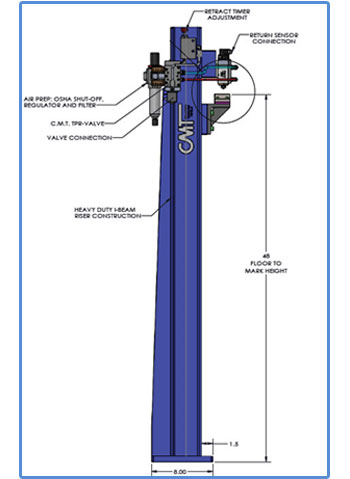

Figure 4 Example station drawing - part rest and height designed per application

www.columbiamt.com

For more information – info@columbiamt.com

|

|

Figure 1 Complete Mite-E-Mark Station

These new stations are designed for robotic work cells and come ready to mark with a selection of air impact markers, all required valves, impact marker mounts, part rest, and optional Fieldbus for PLC communications.

Figure 3 Close-up of Mite-E-Mark showing backup detail

CMT's complete automation cell station includes:

• Air impact unit

• Filter, Regulator, Lubricator and OSHA Safety lockout

• 4 Way valve with air timer

• Heavy Duty Riser Construction

• Part rest/marking backup

• Optional Field Bus

• Optional wired return sensor

• All mounted and assembled – ready to install in automation cell

|

|

|

| | |