|

|

| |

|

| |

|

Automated Restock Alerts Keep Production Lines Running

|

| |

| |

|

|

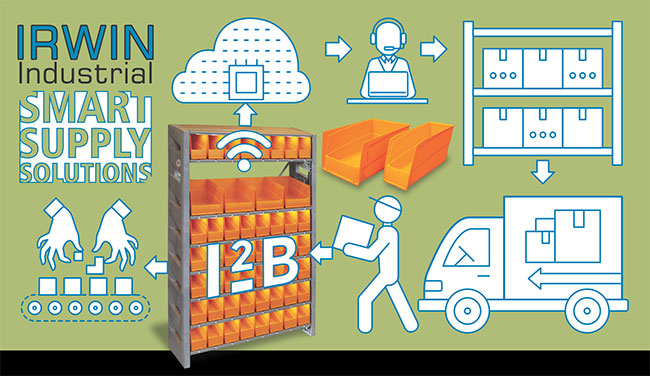

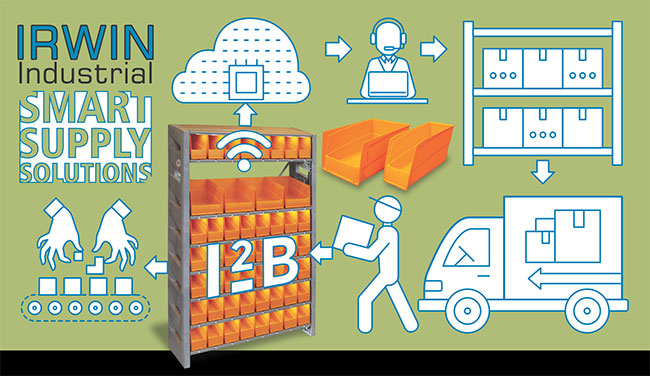

IRWIN Industrial has added a new dimension to its suite of integrated part supply solutions.

Each IRWIN Intelligent Bin (I²B) automatically detects inventory levels and instantly sends alerts to IRWIN for informed replenishment, eliminating the need for counting trips. So, no more safety stock or emergency orders, and most importantly, no more lines down.

|

|

|

| |

| • |

|

Reduce Order Activity

|

|

| • |

|

Prompt Low-Stock Notifications

|

| |

| • |

|

Flexible Configurations

|

| |

| • |

|

Supply-Base Consolidation

|

|

|

|

|

Multiple detection levels provide fill-status per bin. You'll get 24/7 visibility, insights, and analysis to optimise your operations, inventory and processes. You'll also eliminate disruptive and expensive out-of-stocks.

Streamline your supply chain

Consolidation of vendors across many possible part categories means fewer orders and expedites, while providing economies of scale and lowering incoming freight costs. You get reduced, but assured inventory and space-savings; allowing your organization to optimize its resources, focus on core competencies and meet strategic goals.

Keep bins full and manufacturing lines running

IRWIN Intelligent Bin Systems eliminate inefficient manual bin counts and stock outs. That keeps production lines and assembly cells uninterrupted – and profitable.

For more information, please see the article IRWIN INTELLIGENT BIN SYSTEMS, which includes a video. You can also download the brochure; or email Richard Michaud, Irwin’s Director - Supply Chain Solutions.

|

|

|

|

|

|

| | |