| |

| |

|

|

| |

|

|

@{mv_date_MMM d, yyyy}@ |

|

| |

This week, Canadian Biomass and Canadian Forest Industries will be focused on best practices, technical information and solutions for keeping pellet and sawmill operations safe, AND we’ll be hosting a free webinar on dust hazard analysis on June 25 at 1:00 p.m. EST.

» Read more...

This week, Canadian Biomass and Canadian Forest Industries will be focused on best practices, technical information and solutions for keeping pellet and sawmill operations safe, AND we’ll be hosting a free webinar on dust hazard analysis on June 25 at 1:00 p.m. EST.

» Read more...

Dust suppression has become an increasingly important challenge in biomass operations. BossTek's Mike Lewis shares what to look for when selecting dust control equipment.

» Read more...

The Wood Pellet Association of Canada (WPAC)’s Safety Committee, in collaboration with the BC Forest Safety Council, the Manufacturing Advisory Group, and WorkSafeBC, have developed tools to improve safety and lower the risk when working around wood fibre storage.

» Read more...

|

| |

|

|

| |

|

| |

David Murray, co-chairperson of the Manufacturing Advisory Group and corporate safety, HR and environment manager for Gorman Group, shares lessons learned from the 2012 B.C. combustible dust explosions.

» Read more...

David Murray, co-chairperson of the Manufacturing Advisory Group and corporate safety, HR and environment manager for Gorman Group, shares lessons learned from the 2012 B.C. combustible dust explosions.

» Read more... |

| |

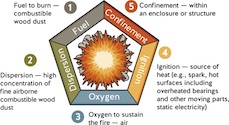

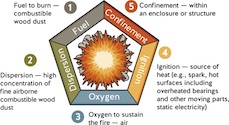

Do you know what kind of dust is in your workplace? Where does it accumulate? What ignition sources are present? A risk assessment will help you identify any potential risks of a combustible dust explosion in your facility.

» Read more...

Do you know what kind of dust is in your workplace? Where does it accumulate? What ignition sources are present? A risk assessment will help you identify any potential risks of a combustible dust explosion in your facility.

» Read more... |

| |

|

| |

In a step by step series, WorkSafeBC outlines potential scenarios and the controls required to avoid a dust collector explosion.

» Read more...

In a step by step series, WorkSafeBC outlines potential scenarios and the controls required to avoid a dust collector explosion.

» Read more...

Dust collectors account for 42 per cent of explosions, which makes them a high risk for potential injury and damage to a facility where inlet duct explosion protection is not installed. But in a 2018 survey, over 75 per cent of dust collectors did not have inlet explosion protection.

» Read more...

|

| |

|

| |

|

|

| |

| |